Support services UGS

Mining Rescue Service

NAFTA has a special rescue unit for emergencies, the Mine Rescue Service. The mine rescue service is part of the Slovak Republic’s integrative emergency services, playing a role at two levels:

- Plant Mine Rescue Station staffed by operations personnel

- Main Mine Rescue Station, composed of professional mine rescuers

Mine rescue station members regularly engage in workover exercises covering different types of emergencies and are presently cooperating with all other rescue units.

Services for External Partners

Our team of experts from the Main Mining Rescue Station also provides outside partners with specific training, drills and services.

Specific courses are provided in operating and maintaining breathing apparatuses.

Besides courses, different training exercises are offered to external partners:

- Training in a smoke environment

- Firefighter training drills

- Airplane cockpit drills – fire and smoke training accepted by the Slovak Republic Civil Aviation Authority

- Drills at a training well according to customer requirements

Other services offered include:

- Special operations - drilling valves and fittings under pressure

- Filling pressure cylinders

- Portable measuring and indicating equipment

- Working in unbreathable environments

- Organizing teambuilding with the focus on practical fire protection training

Natural Gas Laboratory Services

The range of laboratory analyzes of natural gas includes:

Composition by gas chromatography

- hydrogen and inert gases – CO2, N2, O2, H2, He (ISO 6974)

- hydrocarbons - methane, ethane, propane, i-butane, n-butane, i-pentane, n-pentane, neopentane, hexane (ISO 6974)

- heavier hydrocarbons as C6+ group (ISO 6974) or individual fractions Cx up to C20 (ISO 6975 and ISO 23874)

- sulfur compounds (ASTM D-5504)

Stabile C and H isotope ratios by GC-IRMS system, with evaluations according to Bernard, Schoell, etc.

- δ13C (vs. VPDB)

- δ2H (vs. VSMOW)

Calculations

- Calorific values, density, relative density and Wobbe indices from gas composition at various reference pressures and temperatures for combustion and volume metering (ISO 6976)

- Using software GasVLe (DNV GL) - water content derived from known water dew point (ISO 18453), hydrocarbon dew point from composition up to C20 (ISO 23874 and ISO/TR 11150)

Gas sampling

- Into pressure cylinders 0,5-1L at operational pressures up to 20 MPa (ISO 10715, API 14.1, GPA 2166)

- In gas sampling bags made of chemically inert materials (Restek, SKC)

Local spot measurements of dew points in treated natural gas (ISO 6327, ASTM D1142).

References:

Picture 1

Picture 1

Picture 2

Picture 2

Picture 3

Picture 3

Picture 4

Picture 4

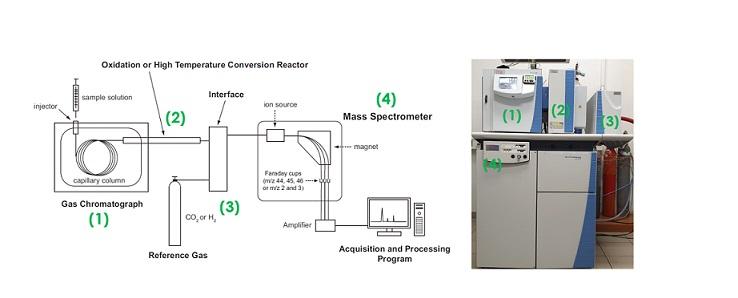

GC-IRMS: Gas Chromatography - Isotope Ratio Mass Spectrometer

The production of natural gas from gas wells, and the use of wells for natural gas storage, must meet many conditions for their safe operation. Gas wells are communication channels between the geological reservoir and surface facilities. But at the same time, they are an artificial technical equipment in a natural geological environment. Interference with the original hermeticity of the rocks, some technical deficiencies during the construction of the well, can generate certain leaks along the subsurface pathways of the well (ISO/TS 16530-2 Well integrity for the operational phase). As a result, in addition to the main and desired flow through tubings, gas can also occur in parts of the well where it should not be, e.g. in the annulus of the columns, and creates increasing pressure in them.

The technical safety of the well and its surroundings in the form of Well Integrity Management has the task of monitoring the occurrence of these pressures in the annulus of the columns. And it also has the task of looking for reasons for detected technical leaks. For this, it is good to know from which source the monitored gas can come - whether it is from the reservoir or whether it is from other, shallower horizons.

From a geochemical point of view, gases originating from different geological periods and processes can be characterized by the composition of stable isotopes. It mainly concerns methane, as it is the basic component of natural gas, and the determination of the content of 13C and 2H isotopes in it. Aids in the form of graphs with δ13C and δ2H values (Schoell and Coleman) or δ13C against the Bernard dryness coefficient (methane content divided by the sum of ethane and propane) are most used to compare the origin of methane.

GC-IRMS analytical system is used to determine δ13C and δ2H values: Gas Chromatography - Isotope Ratio Mass Spectrometer. During the analysis, the components of natural gas must be (1) separated from each other, (2) quantitatively transformed into a suitable measurable form, (3) alternately with the reference gas transported to (4) the MS detector:

Obrázok 8s

Obrázok 8s

The δ13C isotopic ratio shift is calculated to the standard Vienna Pee Dee Belemnite, the isotopic ratio shift δ2H is calculated to the standard Vienna Standard Mean Ocean Water.

In the laboratory of the Division of UGS Nafta a.s. we are dedicated to the targeted collection of gas samples from the surface equipment of wells, chemical analysis by gas chromatography and the mentioned analyzes of stable isotopes in methane or another hydrocarbons of higher content. The measured data are then interpreted by an employee of the geochemistry department.

Slickline Services

Nafta provide slickline/wireline services with 2 truck units and staff of 3 operators and one slickline engineer with IWCF Certificates.

Track units parameters:

Iveco EuroCargo tector 4x4

Built with technology from Leutert in Germany (2003)

- slicklines – carbon steel 2,08 mm and 2,34 mm, stainless 2,34 mm,

- max depth to 6 km

- max load on winch 0,5 t, max load on listed lines 350 kg

- detachable slickline drum

MAN 13.250 4x4

built with technologies LogIn and CanadaTech in Germany (2009)

- slickline – carbon steel 2,74 mm

- max depth to 6 km

- max load on winch 2 t, max load on listed line 450 kg

- cable monoconductor 7/32“ for downhole online pressure and temperature measuring

Typical provided services

Measurements, inspections, sampling

- dumb caliber runs to bottoms

- downhole pressures, temperatures and fluid levels with memory gauges (piezoresistive and quartz)

- downhole minilogging memory tool MLT300 (Canada Tech, ALS Omega Well Monitoring)

- pressures, fluid levels

- thermometry

- CCL

- flowmeter – velocity changes in well completion due to scales, velocity profile in pay zones

- radial flowmeter – influx point in ruptured gravel pack filter

- dowhnole memory B&W camera (Omega Well Intervention)

- inspection of scales and sediments

- inspection of well completion defects

- inspection of fallen downhole tool

- cable online downhole pressures and temperatures for flow tests of wells

- wellhead and downhole sampling of fluids, gases

Slickline Jobs (with jarring)

- in 2 3/8”, 2 7/8” a 3 1/2" completions

- settling and pulling of downhole valves in X landing nipples

- sliding side door shifting

- downhole sediments sampling

Obrazok 9 EN

Obrazok 9 EN

Diagnostics & Detection Services

Besides normal maintenance of storage facility equipment, NAFTA’s maintenance department is providing new specialist work that covers predictive and diagnostic maintenance of critical infrastructure.

- Detecting and quantifying natural gas leaks through optical gas imaging (OGI) using infrared cameras with sensors that are designed to detect hydrocarbons and an application to determine the amount of leaking gas.

- Diagnosing control valves through a set of diagnostic instruments supported by an application that diagnoses how valves are functioning and predicts the probability of future failures/general overhaul.

- Diagnosing ball valve tightness through a set of measurement instruments and know-how to verify the degree of tightness for most valves above DN100 as an important foundation for capital projects.